Our Equipment Trailers are designed with lower deck heights to make transporting your vehicles, tractors, and powered equipment safe and easy. You can also choose super-wide deck options. These trailers can haul from 4,500 to over 17,000 lbs, depending on your needs.

8" Channel Equipment (C8)

20 – 40' Lengths

83" Deck Width

16,000 lbs GVWR

10,550—19,020 lbs Load Capacity

6" Channel Equipment (CC)

16 – 24' Lengths

83" Deck Width

14,000 lbs GVWR

11,300—20,780 lbs Load Capacity

New!

6" Channel Equipment (CD)

18 – 22' Lengths

83" Deck Width

14,000 lbs GVWR

10,980—11,380 lbs Load Capacity

5" Channel Equipment (CE)

16 – 22' Lengths

83" Deck Width

9,899 lbs GVWR

7,249—7,579 lbs Load Capacity

New!

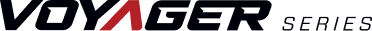

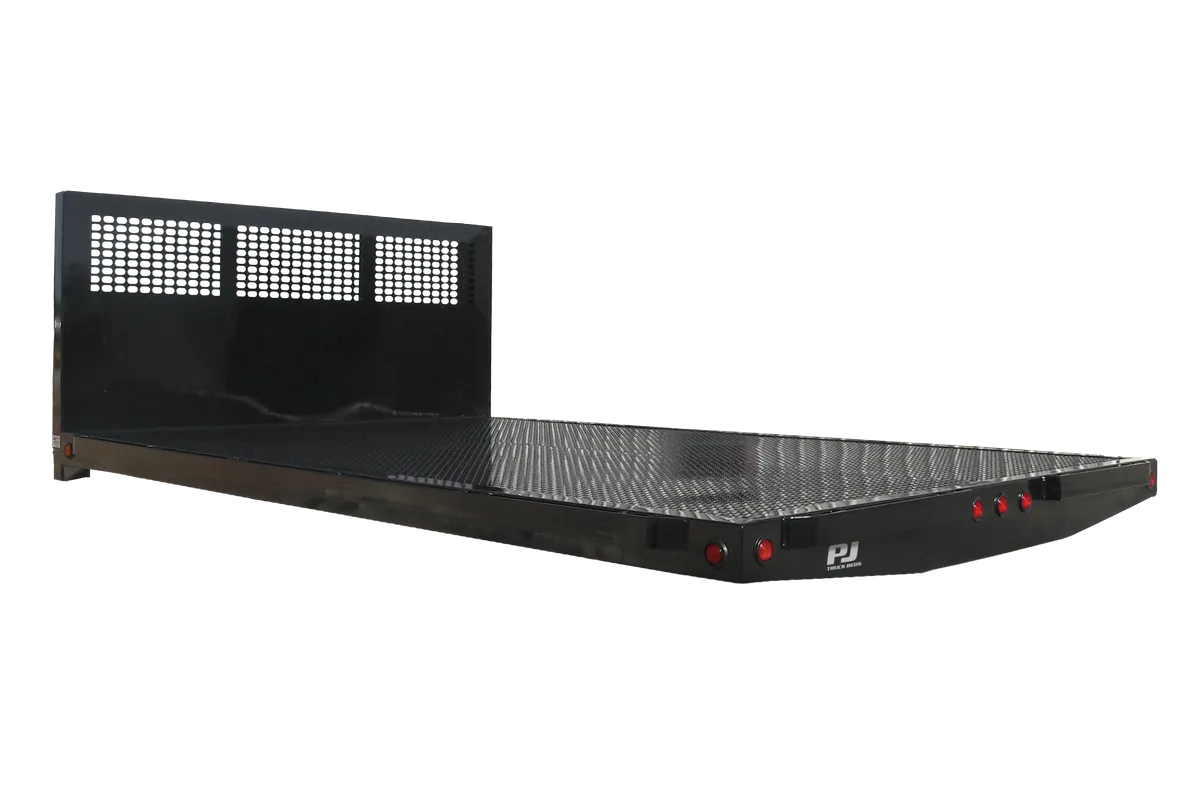

Voyager Series

Seamless I-Beam Equipment Trailer (EV)

16 – 24' Lengths

83" Deck Width

15,400 lbs GVWR

12,135—12,545 lbs Load Capacity

10" Pro-Beam™ Equipment (H5)

20 – 26' Lengths

82" Deck Width

20,000 lbs GVWR

12,400—16,738 lbs Load Capacity

8" Pro-Beam™ Super-Wide Equipment (H6)

20 – 26' Lengths

102" Deck Width

16,000 lbs GVWR

11,940—13,960 lbs Load Capacity

10" Pro-Beam™ Super-Wide Equipment (H7)

18 – 32' Lengths

102" Deck Width

20,000 lbs GVWR

12,000—16,600 lbs Load Capacity

Equipment Trailer Features

Known for their versatility, durability, and design, our Equipment Trailers are loaded with great features and benefits.

Radial tires feature better fuel economy, less vibration, a softer ride, and extended life due to less heat being generated by the tire. Radial tires are the only way to go on trailers for equipment hauling.

Our Equipment Trailers include a Bulldog™ coupler as a standard feature—the toughest, most durable coupler in the trailer industry.

Note: The CC, C8, B6, B8, & P8 models get height adjustable couplers allowing you to level the trailer with the towing vehicle.

Our Equipment Trailers receive treated no. 2 southern yellow pine for decking—a pressure treated lumber that’s known for its high strength and durability.

When you order a gooseneck Equipment Trailer, it comes with an I-beam neck and riser. Our I-beam necks are stronger and last longer than the commonly used c-channel necks, and they’re standard, not an upgrade.

Every one of our Equipment Trailers features Lifetime LED tail lights standard (model year 2017 & newer) with a lifetime warranty. LED lights are brighter, faster, draw less current, and last longer than incandescent lights.

Our Equipment Trailers use a wiring harness that’s enclosed in steel conduit throughout the frame of the trailer to protect wiring from ice, road debris, and physical damage. Plus, each light is simply plugged in and makes replacement easy.

Flush mounted lights inside the frame protects them from damage and debris—keeping your trailer legal and safe for whatever adventures you go on.

On our 14k Equipment Trailers (CC,C8,B6,B8,P8), we use 3″ channel for cross-members on 16″ center for increased deck strength.

Our Equipment Trailers are built in compliance with the National Association of Trailer Manufacturers trailer safety regulations.

All our Equipment Trailers feature a wrap tongue that’s extended to the front of the fender—significantly increasing the strength and rigidity of the entire frame.

For a Equipment Trailer that lasts, it has to be built on a solid foundation. Our trailers take frame strength to the next level—and we have the warranty to prove it.

We offer deck lengths up to 44′ on our 8″ channel models (C8 & B8)—popular for hauling cars and with hot shot companies.

We offer three dedicated models with deck widths of 102’’ (B5, B6, & B8). In addition, these models include heavy-duty drive over fenders—making them extremely versatile for hauling a variety of vehicles and cargo.

We fabricate many of our frame components on CNC plasma tables. Enabling us to create superior components, it gives us the ability to customize the exact component we need for each model to make sure your trailer is built to the quality you demand.

You’ve got an endless list of goals to achieve, and we don’t believe you should settle for a trailer that isn’t what you need to chase your dreams. That’s why we offer a wide variety of options, including steel floors, winches, HD gates, flip-up ramps, and more.

12Most of our Equipment Trailers are wired with a weatherproof junction box to keep wiring clean and protected from the elements.

FREQUENTLY ASKED QUESTIONS

Rinse with water, then use mild soap and a soft cloth or brush. Focus on fenders and high-traffic areas. Avoid harsh chemicals. This simple solution helps preserve the finish and reflect the quality of our products.

Store in a dry, covered space if possible. For outdoor storage, a breathable cover protects from weather and debris. PJ Trailers is here to offer you maintenance and care tips to maintain longevity.

Use a damp cloth and mild detergent. For stubborn dirt, try a soft-bristle brush. Dry completely to prevent water spots. Your PJ Trailers supplier may also recommend finishes that complement this care routine.

Lubricate hinges and moving parts occasionally with a light oil or grease, and remove excess to avoid grime buildup. Our company recommends this step – and other simple maintenance routines — to help ensure your trailer works as hard as you do for as long as you require.

Check visually after each use. Frequent inspections help avoid buildup and preserve the trailer’s appearance. A clean trailer also reflects the care we put into sales and service as your trusted seller.